Design Features | Rally Horween® Leather Quick Release

Skillfully crafted to evoke the nostalgia of 1960s & 1970s speed and motorsport, our Horween® Rally Collection pairs perfectly with chronographs, smartwatches, and tool watches alike. The distinguishing perforations, originally designed to create a breathable strap for racetrack drivers, now makes a signature statement on your wrist.

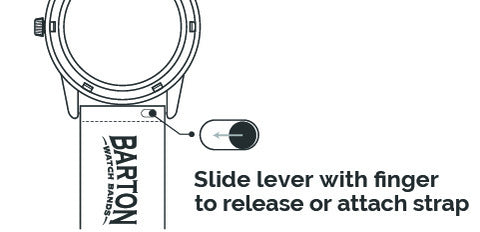

Swap on the Go - Without Tools

Equipped with integrated quick release spring bars that allow you to insert or remove the band in a matter of seconds.

Dublin Leather by Horween® Leather Company

Our Rally Quick Release watch straps feature leather from one of the oldest tanneries in the US. Horween® Leather Company is based in Chicago, which has been tanning and producing high-quality leather for over 100 years. Dublin Horween leather is a vegetable-tanned leather and has been hand-glazed with a waxy feel. This premium treatment allows the natural characteristics of the leather to shine through. Be aware that a natural patina will develop over time, giving this watch band a worn-in, timeless feel. These simple imperfections will add a rich texture to any timepiece.

Padding and Taper

Each strap features padding for comfort and style. The thickness measures 4mm at the spring bar end and 1.8mm near the buckle. Each strap is also tapered and the width at the buckle is 2mm narrower than the width at the watch head.

Fine Stitching

Custom stitching wraps around the full perimeter of the band for both aesthetics and strength. Each band is individually stitched using durability-tested thread.

Optimal Fit

Our standard length bands fit wrists 5" - 8" inches in circumference. Please note, watch geometry may also impact fit. If you are not sure whether a band will fit or not, we encourage you to give it a try as we offer a money back guarantee!

Stainless Steel Hardware

Our straps utilize 316L stainless steel buckles, not iron or aluminum. Iron components rust and need to be bulkier and heavier to achieve strength comparable to that of stainless steel. The finish on both treated iron and aluminum parts can weather or wear off, leaving a dull, scrap-metal appearance. If you take a knife to our stainless steel components, you will find a material that 1) is solid all the way through, 2) is difficult to scratch or bend and 3) maintains its initial finish for many years.